We often get asked about the technology we use to laser cut tube and flat sheet steel, the purpose of this article is to provide a basic explanation of how CO2 laser cutting technology works.

Light Amplification by Stimulated Emission of Radiation

Laser cutting is the use of a high power laser beam generated in the resonator of the machine. The laser beam is then directed towards a cutting head through a series of perfectly aligned mirrors, where the laser is finally focused through a lens in order to concentrate the laser beam into a small spot. The now intensified/focused laser beam is capable of cutting through all types of metal such as stainless steel, aluminium, mild steel and more.

Basic Laser machine layout:

Typically, the type of steel being laser cut dictates the type of cutting gas required, for example if we are laser cutting mild steel we use Oxygen. Much like oxy-fuel cutting the oxygen used in the laser cutting of mild steel provides a exothermic reaction process. If we are cutting aluminum or stainless steel we use Nitrogen, in this process the laser beam needs to provide enough energy to melt the material and the nitrogen is simply used to blow the excess or melting material away.

Oxygen cutting vs Nitrogen cutting:

As a simple guide, a thicker metal requires a higher power laser beam to effectively process the metal. However, different materials vary in cutting difficulty. For example stainless steel laser cutting requires more energy than mild steel laser cutting, and laser cutting of aluminum requires more energy again.

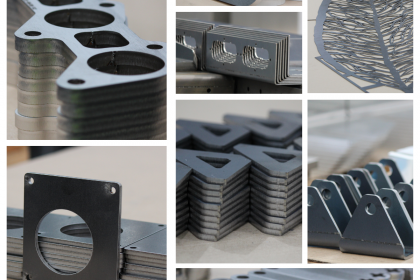

At the GCI Group we utilise this technology to process stainless steel laser cutting of flat sheets, laser cutting stainless steel tube & laser cutting stainless steel RHS. We also offer aluminium laser cutting of flat sheet, and RHS laser cutting of aluminium including aluminium tube, angle and more. In addition to these metals, we commonly laser cut mild steel of various grades in flat sheet. We also offer mild steel tube laser cutting, laser cutting of RHS mild steel, mild steel angle laser cutting and more.

Laser machine layout & cutting nozzle drawings supplied by BOC Limited (2010)