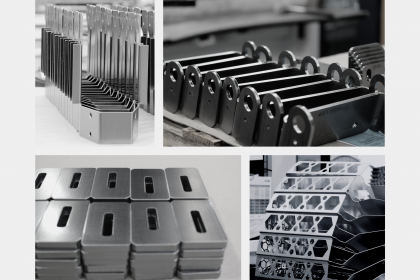

GCI has finalised the commissioning of our brand new robotic weld cell. This latest addition to our capabilities has been achieved with GCI working closely with Robotic Technologies Australia (a Melbourne based robotics company) and BOC – (world gas supplier).

The weld cell was designed and built in house at GCI and integrated by RTA. BOC supplied the high end EWM weld source.

Our companies worked closely together to produce an outstanding productive cell – capable of fast set up times and excellent weld repeat-ability and quality.

For GCI clients this means a reduction in manufacturing time and cost savings that can be passed on to our Gold Coast and Brisbane clients

Because of our close association with RTA and BOC on the design of the cell – we were able to focus its capabilities to meet specifications that would work well with our existing repeat weld products and maximize it potential for future projects and clients. This included giving the cell two weld stations to enable loading and unloading of component whilst keeping the robot welding – maximizing efficiency.

The welding cell can handle parts up to 1800mm x 800mm x 1000+mm

For a demonstration or to discuss component manufacture contact our sales team or call us now on 07 3807 0300