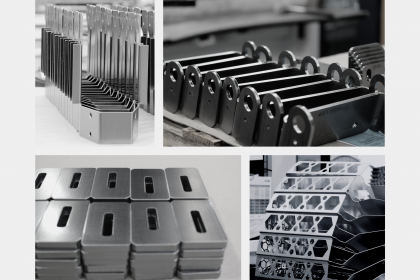

We are excited to announce the latest addition to our manufacturing facilities – the TRUMPF TruBend Cell 5000. At GCI Group we continuously invest in cutting-edge technology to elevate our standards for precision and efficiency, all with the aim of better serving our valued clients like you.

We invite you to witness our TruBend Cell 500 in action by scheduling a visit with our sales team. See firsthand how we can bring your ideas to life.

Here’s how our new addition directly benefits you:

-

Faster Turnaround Times: Increased capacity means shorter lead times, ensuring you receive your parts promptly.

-

Consistent Quality: Enjoy the assurance of consistent and repetitive quality in every part we produce.

-

Cost Savings: With remarkable capability of up to 12 bends per minute the cost of folding complex multi-fold parts is significantly reduced.

-

Exceptional Handling Capacity: Our TRUMPF TruBend Cell 5000 excels at handling higher volume orders without compromising on quality.

-

Flexibility: Whether you require bending delicate or oversized parts, our system accommodates any component geometry with ease.

-

Precision and Efficiency: Benefit from offline simulation, allowing for visualization of the bending process beforehand, ensuring flawless production from the outset.

-

First Part Perfection: Our angle measuring system guarantees consistently precise angles, ensuring the first part is as perfect as the last.

-

Enhanced Setup Efficiency: With a 4-meter bed length and Toolmaster automation we can set up multiple operations quickly and efficiently.

At the heart of the Bendcell 5000 is its advanced automation technology, which streamlines the bending process like never before. By automating key tasks, such as material handling, tool setup, and bending operations, this machine ensures unparalleled consistency in every bend. Gone are the days of variability and manual errors—now, each component is precisely formed to the exact specifications, meeting the highest quality standards every time.

One of the most significant benefits of the TRUMPF Bendcell 5000 is its ability to deliver jobs in a significantly shorter time frame. Thanks to its automated workflow and optimised processes, lead times are drastically reduced, allowing us to meet tight deadlines without sacrificing quality. Whether it's a small batch or a large-volume order, this machine excels at getting the job done quickly and efficiently.

Moreover, the Bendcell 5000 is a game-changer when it comes to reducing the error rate in production. With its advanced sensor technology and real-time monitoring capabilities, potential issues are identified and addressed before they can impact the final product. This not only ensures superior quality but also minimises costly rework and waste, saving both time and resources in the long run.

Another standout feature of the Bendcell 5000 is its exceptional capacity for handling higher-volume orders. Equipped with a robust and versatile design, this machine is capable of bending a wide range of materials and thicknesses with ease. Whether it's mild steel, stainless steel, or aluminum, the TRUMPF Bendcell 5000 delivers consistent results, even in high-demand production environments.

In conclusion, the TRUMPF Bendcell 5000 represents a significant leap forward in bending technology, and we're proud to integrate it into our operations at GCI Group Australia. With its automated functionality, reduced lead times, decreased error rates, and high-volume capabilities, this machine is poised to elevate our manufacturing capabilities to new heights. We look forward to leveraging its power to deliver even greater value to our customers and continue driving innovation in the industry.

At GCI we prioritize quality and service above all else, and customer satisfaction is at the heart of everything we do. Whether you have to repeat forward orders or smaller parts processing needs our bend department is fully equipped to handle it all.

More Exciting News:

The next machine is on the water and is going to be an industry game changer!