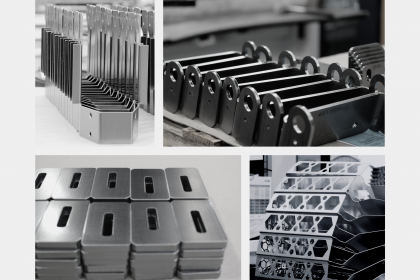

TRUMPF TruBend Cell 5000 added to our manufacturing capabilities

We are excited to announce the latest addition to our manufacturing facilities – the TRUMPF TruBend Cell 5000. At GCI Group we continuously invest in cutting-edge technology to elevate our standards for precision and efficiency, all with the aim of better serving our valued clients like you. We invite you to witness our TruBend Cell 500 in action by scheduling a visit with...

continue...