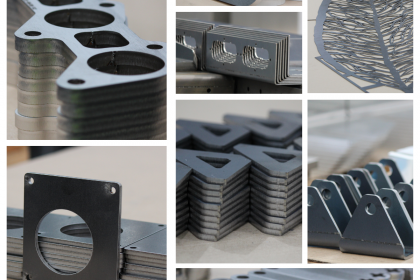

At GCI Group, we blend automated welding technology with the expertise of skilled boilermakers and sheet metal specialists to offer unparalleled welding and fabrication solutions. By combining state-of-the-art machinery with hands-on craftsmanship, we consistently deliver high-quality, cost-effective projects to meet the diverse needs of our clients.

Advanced Welding Solutions: Robotic and Manual Expertise

With two robotic welders integrated into our operations, we bring unmatched precision and consistency to every project. Automated welding ensures flawless, repeatable results while reducing lead times and costs, making it the perfect choice for high-volume production runs.

However, technology is only part of the equation. Our highly skilled boilermakers and sheet metal experts collaborate to provide custom, flexible solutions for complex jobs that require manual craftsmanship alongside automation. This unique blend of talent and technology allows us to take on a wide range of projects, from intricate designs to large-scale fabrication.

Our Welding Methods

To accommodate the specific needs of our clients, we offer multiple welding techniques:

- MIG (Metal Inert Gas Welding): Ideal for heavy-duty fabrication with a focus on speed and reliability.

- TIG (Tungsten Inert Gas Welding): Perfect for precision welding, especially for thin materials and intricate designs.

- Spot Welding: A quick and effective method for joining thin sheets of metal, commonly used in assembly lines.

Whether your project requires robotic precision, manual craftsmanship, or a combination of both, GCI Group has the right solution for you. You can find more information here.

Ask for a free quote

If you have a project, do not hesitate to give us a call or ask for a free quote.