- 3d Modelling

- Laser cutting

- Tube laser cutting

- Fabrication

- Powder coating

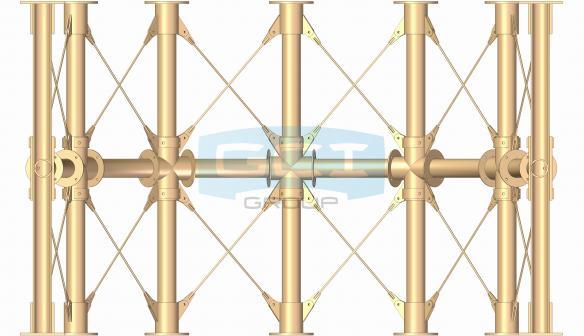

When Hansen Yuncken was awarded head contractor for the supply and construction of the FACE experiment for the University of Western Sydney, the contract required the construction of 6 tower assemblies. Each tower had 32 masts for the purpose of venting C02 over old growth forest for scientists to measure the effects on the vegetation growth over the next 15 years.

It was an intricate project requiring a high percentage of prefabrication to facilitate the minimum of disruption to the natural environment. While schedules and targets inevitably altered with so many contractors and suppliers working together our flexibility enabled us to adapt to reach our fabrication targets.

Fundamentally, it was our precision in the fabrication of the individual pieces that enable it to all come together onsite, providing the solution for the projects designers ‘minimalist onsite erection’ concept. This is another example of gold coast laser cutting.

Hansen Yuncken, Western Sydney

The GCI Group came highly recommended and after the tendering process proved to be very competitive on price. A project like this requires a lot of cooperation from all contractors and suppliers. The GCI Group proved to be both flexible and reliable. While schedules and targets inevitably change with so many contractors and suppliers working together The GCI Group was continually able to adapt and help out. The quality of their work was excellent, allowing the designers concept of erection to go according to plan and allow each piece to fit together with ease. Based on my experiences with the company I would have no hesitation in recommending The GC Industry Group as a quality steel supplier.