Why we do what we do?

We believe in challenging the status quo around Australian manufacturing, we believe that Australian manufacturing has a place in the global market and we are committed to growing this industry.

How we do what we do?

By bringing a new level of professionalism to the industry, we have a commitment to manufacturing precision components and committing to a firm completion date. We invest in dedicated people to operate the latest manufacturing technology. Every day we strive to improve how we do business.

What we do?

Manufacture precision components from singular parts to large complex assemblies to the highest possible quality for clients across Australia. We are proud that many of the items we manufacture are exported across the globe or make up parts of trucks, cars and buses on Australian roads.

Company History

First CNC Laser

This is where it all started!, our first CNC laser cutting machine was commissioned in a small factory in Molendinar on the gold coast in August 2003.

First Trumpf Laser

GC Laser cutting celebrated its first birthday with the purchase of its first brand new Trumpf CNC Laser machine. This was the start of what is today a strong relationship between the German manufacturer Trumpf and the Australian agent Headland Machinery!

99 Lahrs Road, Ormeau

Business growth resulted in a need for more space, this upgrade to a new 2500m2 facility also meant we could offer new services to our clients!

Second Trumpf Machine: 3030 Rotary Laser

Expanding into a larger factory allowed us to commission our second trumpf machine. This was a real step change in capabilities, allowing GCI to laser cut tube, RHS, SHS and more!

First Trumpf CNC Press Brake

Another expansion of capabilities, the first CNC press brake was installed and completed the first client job January 2008

New Trumpf 3030 laser

Third new Trumpf laser installed to cater for business growth, a Trulaser 3030

103 Lahrs road, Ormeau

Expansion into this facility allowed the growth and addition of new services such as Fabrication & General Machining.

CNC Band-saw

Business growth demanded more in house capabilities, the addition of the first CNC band-saw provided solutions to our clients problems.

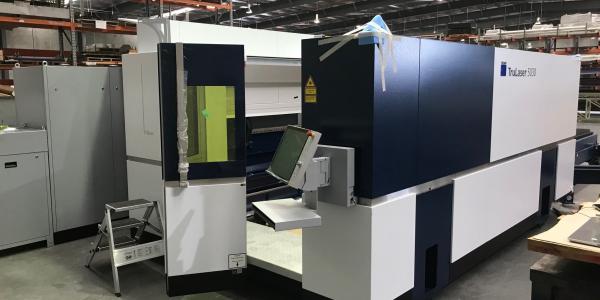

New Trumpf 5030 Laser

Additional laser to cater for business growth and expand the capabilities offered to our clients, this is the 4th new Trumpf Laser!

2nd Trumpf press brake

An additional CNC press brake added to our capability

95 Lahrs road, Ormeau

Expansion into a new facility at 95 Lahrs road Ormeau, allowed GCI to Launch its Coatings department with in house powder coating.

3rd Trumpf Press Brake

The continual expansion & growth of GCI has resulted in an additional Trumpf press brake, with this third addition we have significantly increased our capacity in the department

47 Business Street Yatala

The move into a purpose built facility (6500M2), has allowed GCI to bring all services under one roof and cater for further business growth.

Robotic Welding Cell

This investment set out to cater for repetitive welding jobs and ensure GCI continue providing competitive solutions for its clients.

4th Trumpf Press Brake

The continual expansion & growth of GCI has resulted in an additional Trumpf press brake, with this fourth addition we have significantly increased our capacity in the department

New Trumpf TruTube 7000 Laser!

GCI's 9th new Trumpf Machine! This new 6 axis laser has led to GCI providing the most efficient solutions to our clients

5th Trumpf Press Brake

To Cater for business growth in 2018 & beyond, GCI install a fifth Trumpf press brake.

New 8KW Trumpf Fibre Laser

GCI now operate 5x Trumpf Lasers & this state of the art machine greatly increases efficiency & productivity in our laser cutting department.

STOPA Sheet Metal Automation

This automation is a laser cutting game changer, combined with our 5x Trumpf Lasers this means the GCI group boasts the largest laser cutting capacity in QLD.

The GCI Group came highly recommended and after the tendering process proved to be very competitive on price. A project like this requires a lot of cooperation from all contractors and suppliers. The GCI Group proved to be both flexible and reliable. While schedules and targets inevitably change with so many contractors and suppliers working together The GCI Group was continually able to adapt and help out. The quality of their work was excellent, allowing the designers concept of erection to go according to plan and allow each piece to fit together with ease. Based on my experiences with the company I would have no hesitation in recommending The GC Industry Group as a quality steel supplier.

Designed, engineered and built in Australia.

To our team at Bustech this statement is not some marketing spin we expound whenever convenient. It is the very foundation upon which every bus we build leaves our manufacturing floor.

To ensure that foundation remains strong we look to engage with like minded suppliers. As such the GCI Group has become a welcome partner in our pursuit of excellence. Their quality control and ability to fabricate to the finest tolerances helped us pioneer the ultra-low floor bus that is as stylish and durable as it is innovative.

We demand as much of our suppliers as we do of ourselves, which is exactly why we work and trust in GCI.

The Commonwealth Games have now come and gone!

As a contributor for the delivery of the Games, I just wanted to say a massive thank you for GCI’s patience and cooperation in supplying the bike racks.

I have attached a couple of images if you were interested in the rack’s usage during the Games.

Hope everything is well and thanks again for helping to support Gold Coast’s shift to an active City.

SDT has engaged The GCI Group to fabricate our driving simulators.

We have been impressed with the customer service, value, build time and build quality.

The GCI Group has improved our end-product and been refreshingly easy to deal with.

Our customers are receiving the best possible driving simulator frame, thanks to GCI.

Redmond Gary Australia has had a long standing relationship with GCI. For at least the last 10 years GCI has been one of our main suppliers for laser cut and folded parts manufactured from steel. On some occasions they have assisted us with fabrication when demand outstrips our own capacity. It is important to Redmond Gary Australia to have a trusted supplier who has ISO 9001 accreditation and can be relied upon to deliver parts and components of high accuracy in the correct quantities on time to meet our production schedule.

I would not hesitate to recommend GCI for the supply of steel components.

To whom it may concern

I want to take this opportunity to thank you for the supply of our Ambulance parts over the past 12 months.

Varley has spent considerable time looking for a reliable, cost competitive Laser supplier. After exhausting the market in Queensland, you were the only supplier that has proven to be consistent in delivering our products on time and defect free. Working in with our lean system has also proven to benefit us by saving hundreds of man hours in our stores.

Working with your team has been a pleasure and has been nothing but professional. The after sales service is also of a very good standard and trust that this will continue into the future.

We at Varley look forward to working with your team with all upcoming future contracts. I can highly recommend your services.

To the GCI team,

I want to thank you for assisting me with the alloy tray & canopy for my new work vehicle. Before I found the GCI group I spent considerable time evaluating my options, I was faced with cheap substandard canopies, or overpriced solutions from the leading suppliers that found it “too hard” to cater to my specific requirements. You have been a pleasure to deal with, I’m happy with the end product & the cost was very competitive.

Thanks Again

Matt