One of the most common questions that we get asked at GCI Group is “what’s the difference between laser cutting and plasma cutting?”

While both methods can effectively cut your metal components, they use entirely different mechanisms to perform that cutting process. They also come with their own unique advantages. Which method you should use for your project will depend on your specific requirements.

| |

Laser cutting

|

Plasma cutting

|

|

Fast cutting process?

|

✅

|

❌

|

|

Capable of cutting finer levels of detail?

|

✅

|

❌

|

|

Energy efficient?

|

✅

|

❌

|

|

Does not emit radiation

|

✅

|

❌

|

|

Material thickness

|

Up to 25 mm

|

Up to 50 mm

|

What is plasma cutting?

First developed in the 1950s, plasma cutting involves generating a stream of ‘plasma’ to cut through conductive materials.

Plasma cutting works by firing a high-velocity mixture of gases – including nitrogen and hydrogen – towards the workpiece. An electric arc forms within the gas, which creates an electrically conductive channel of ionised gas, i.e. plasma. Electricity then travels through the plasma channel, which produces enough heat to cut through the metal.

When should I use plasma cutting?

Plasma cutters can cut virtually any conductive metal – including stainless steel, aluminium, brass and copper. It’s particularly well-suited for thick metal, up to 50 mm. If your project involves cutting highly reflective or very thick sheets of metal, plasma should be your preferred cutting method.

Because plasma cutting is less precise, it is not ideal when your project requires higher levels of detail.

What is laser cutting?

As the name suggests, laser cutting utilises the power of optical light. It involves firing a focused laser beam to cut the material

There are two types of lasers: CO2 and fibre lasers. The high-power laser used for CO2 laser cutting is reflected internally by several mirrors until it reaches sufficient energy levels to project a stream of monochromatic coherent light. Fibre lasers, however, do not include mirrors. Instead, diodes and fibre-optics generate the cutting beams.

When should I use laser cutting?

Because laser cutting offers a much higher level of precision compared to plasma cutters, we recommend using laser cutting for applications that require tighter tolerances or more precise cuts. It is also generally faster than plasma cutting, which is crucial when your project has a short turnaround time.

We recommend laser cutting for all of your component cutting needs on materials under 25 mm thickness.

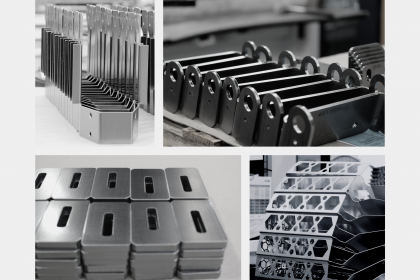

Laser cutting from GCI

At GCI Group, we have two in-house laser departments that utilise the latest Trumpf laser cutting machines – with both CO2 and fibre lasers. Our 2D laser cutting and edge-rounding capabilities for flat sheets is cost-efficient and precise. We can successfully cut and detail complex designs for both small and big batch production.

Our second service is our dedicated tube laser, which can handle the following in stainless steel, mild steel and aluminium:

At GCI, we’ve made a significant investment in the latest technology and machinery to ensure we are at the forefront of the laser cutting industry. As a result, we manage the most automated laser cutting facility in Queensland and the largest material handling system in Australia.

Our commitment to providing the best in laser cutting will not only ensure a higher quality and detailed product but a speedier turnaround for your project.